Operation

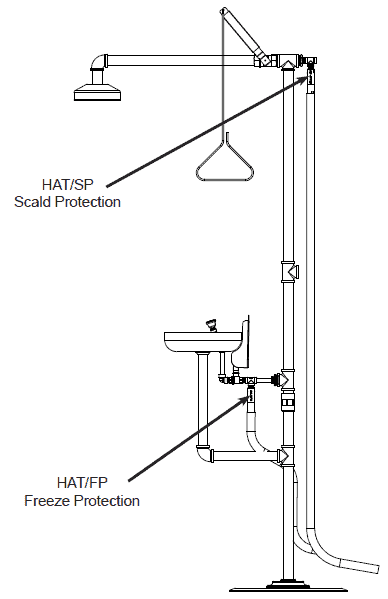

The HAT/SP scald protection valve should be installed at the highest point on an emergency safety station to continuously sense and automatically bleed off the excessively hot water. Depending on installation orientation, the thermal actuator at the heart of the valve will sense either the ambient or fluid temperature. It will modulate the valve open to establish flow if the temperature is above the valve’s set-point.

Cooler water from the supply will backfill the line and cause the valve to modulate closed once the water temperature falls to 10°F below the open set-point.

When installed in the ambient sensing position (standard flow), the thermal actuator will respond to atmospheric temperature changes to initiate flow and then respond to water temperature once flow is established.

- More conservative choice

- Opens sooner than fluid sensing on dropping temperatures

- More tolerant of dirty water

- Good choice for warmer climates

The actuator will always respond to the water temperature when installed in the fluid sensing position (reverse flow).

- Used as a backup with insulated piping or heat tracing

- Ideal for colder climates

- Results in less nuisance dumping/draining

Typical Applications

A safety hazard for plant personnel can occur when utilizing safety showers, facewash, or eyewash stations if overheating the pipes caused by solar radiation or steam/electric tracing results in extremely high temperatures at the point of use. The HAT/SP scald protection valve prevents this safety hazard.

When installed in safety showers, eyewash stations, and other locations exposed to the same source of overheating as the system, the HAT/SP will be heated just as the pipe system. The valve will open to establish flow until the overtemperature water is eliminated and it will then modulate closed.

Design Features

- Exclusive self-actuating Thermoloid® wax blend thermal actuator

- Stainless steel body, fittings, spring, and plug

- Compact, low-mass – fast response

- Corrosion-resistant – long service life

- Ram-type plug for reliable and tight shutoff

- Installs in any orientation

Benefits

- Self-operating, no external power source required

- Meets ANSI Z358.1 standards

- Keeps operator safe from scalding

- Discharges the minimum amount of water

- Some valves are NSF/ANSI/CAN 61 & 372 Certified

Ordering

PART NUMBER | DESCRIPTION2 |

124-302100-XXX | ½” HAT/SP-XXX-C-E (Ambient Sensing) |

124-312100-XXX | ½” HAT/SP-XXX-C-SS-E (Ambient Sensing) |

124-702100-XXX | ½” HAT/SP-XXX-C-RF-E1(Fluid Sensing) |

124-712100-XXX | ½” HAT/SP-XXX-C-SS-RF-E (Fluid sensing) |

125-502100-XXX | ¾” HAT/SP-XXX-D-E (Ambient Sensing) |

125-512100-XXX | ¾” HAT/SP-XXX-D-SS-E (Ambient Sensing) |

125-702100-XXX | ¾” HAT/SP-XXX-D-RF-E (Fluid Sensing) |

125-712100-XXX | ¾” HAT/SP-XXX-D-SS-RF-E1 (Fluid Sensing) |