Operation

Utilizing a thermostatic wax actuator, the TV/HAT (Tube Valve/Heat Actuated Trap) freeze protection valve responds only to fluid temperature to control a system. After condensate forms and cools to the valve’s set point, the valve modulates the flow to maintain a constant condensate discharge temperature. During start-up, the TV/HAT is wide open for rapid venting and initial heat-up and then will adjust based on fluid temperature. After shutdown, the valve is self-draining to eliminate freeze damage.

For heating of temperature-sensitive instruments or process fluids, the reduced temperature available for tracing simplifies operations and eliminates overheating problems. For other heat transfer fluids, the TV/HAT freeze protection valve maintains a constant discharge temperature, thus providing the benefits of accurate process temperature control and improved efficiency.

Typical Applications

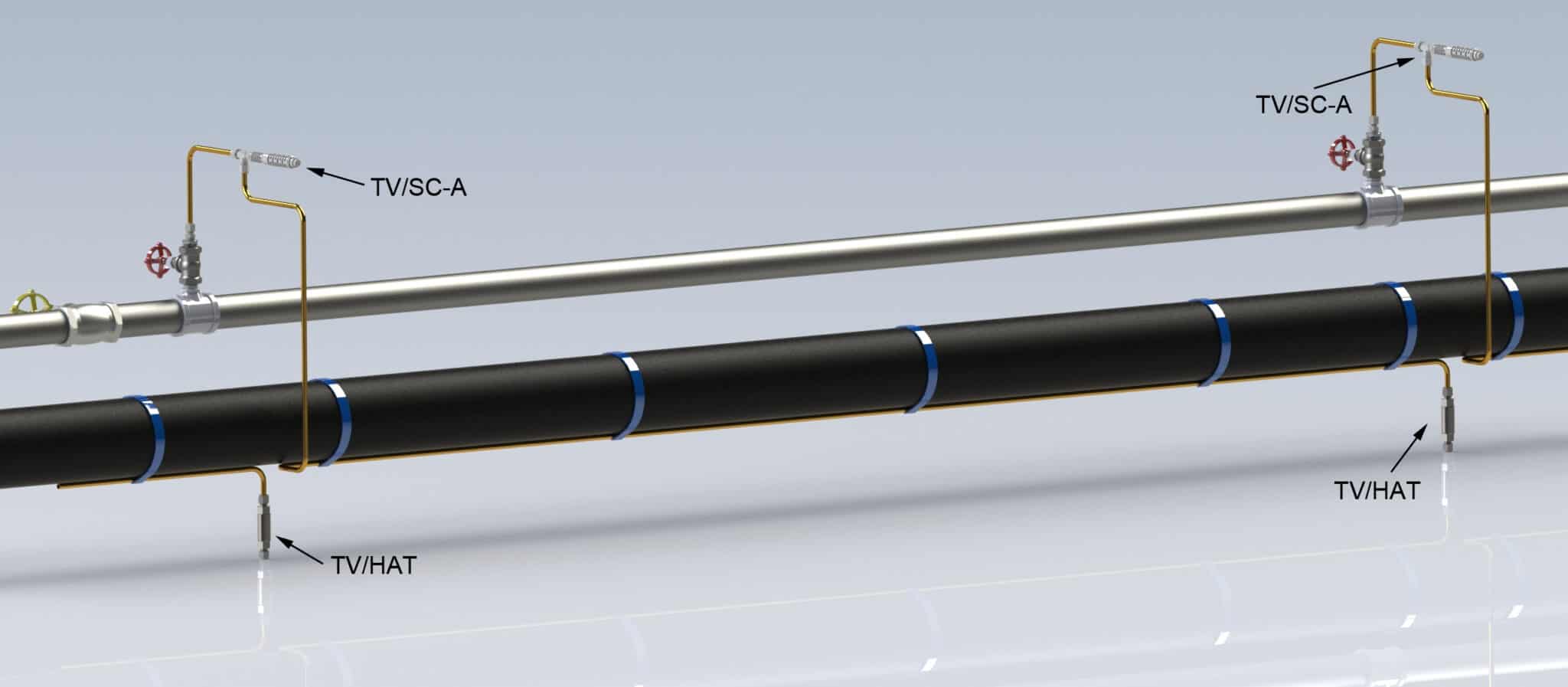

TV/HAT valves are ideal for use in conjunction with tracer tubing and tracing systems using pre-traced tubing bundles. These valves are optimal for replacing conventional steam traps on winterization tracing, instrument tracing, condensate return system freeze protection, tracing for processes under 150°F (65°C), and other applications requiring in-line flow control based on temperature.

Design Features

- Exclusive self-actuating Thermoloid® blend wax thermal actuator

- Stainless steel body, fittings, spring, and plug

- Corrosion-resistant – long service life

- Compact, low mass for fast response

- Ram-type plug for tight reliable shutoff

- Operates in narrow temperature band

- Standard fittings are Parker A-LOK, but Swagelok are also available

Benefits

- Self-operating – no external power source required

- Eliminates live steam losses

- Downstream actuator for greater sensitivity

- Unaffected by pressure variations

- Wide choice of set points

- Operates in any position

- Easy to install

Ordering

PART NUMBER | DESCRIPTION |

212 - 100X00 - XXX | 1/4” TV/HAT-SS2 |

212 - 110X00 - XXX | 1/4” TV/HAT-SS-SW3 |

213 - 100X00 - XXX | 3/8” TV/HAT-SS2 |

213 - 110X00 - XXX | 3/8” TV/HAT-SS-SW3 |

214 - 100X00 - XXX | 1/2” TV/HAT-SS2 |

214 - 110X00 - XXX | 1/2” TV/HAT-SS-SW3 |

212 - 201X00 - XXX | 1/4” TV/HAT-XXX-S6-X |

213 - 30000X - XXX | 3/8” TV/HAT-XXX-S6-X |

214 - 200X02 - XXX | 1/2” TV/HAT-XXX-S6-X |