Operation

The EcoFlow® mechanical seal support system contains a highly reliable and repeatable thermal actuator that continuously senses the seal water temperature. If the seal water should exceed the specified factory set-point, the valve will modulate open discharging the hot water, displacing it with cool water. This cooler water will cause the EcoFlow® to modulate closed. This cycle will continue to occur as long as excessive heat is transferred to the seal water causing the water temperature to exceed the valve’s factory set-point.

Typical Applications

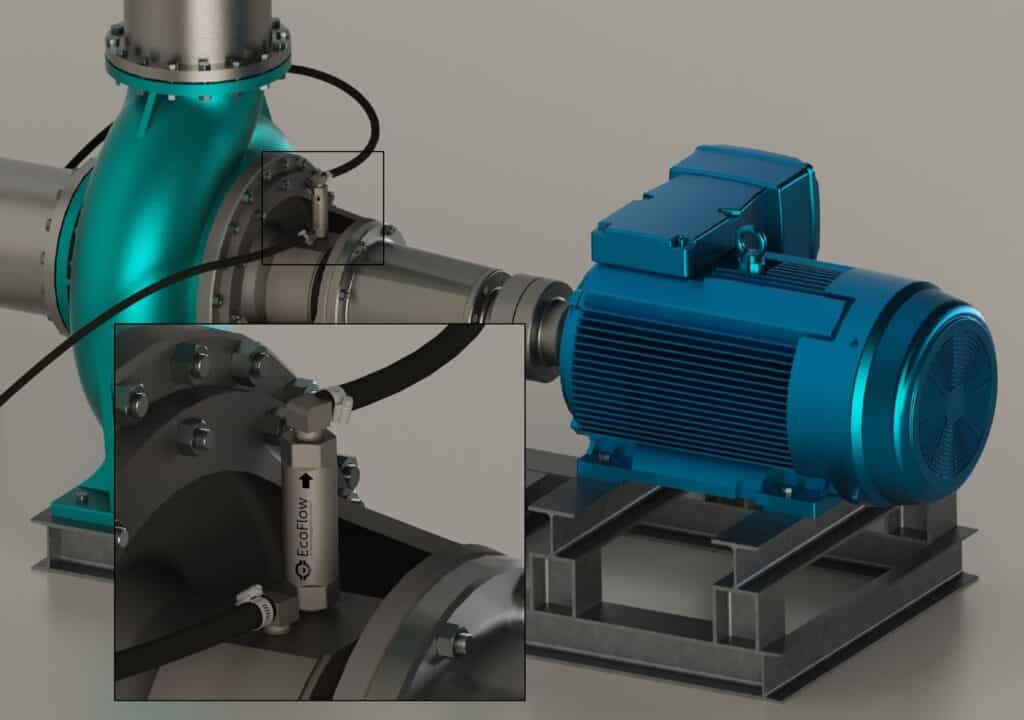

The EcoFlow® valve is installed on the seal water outlet of a mechanical seal to maintain a constant seal water outlet temperature. This increases seal life by ensuring an optimum seal environment while drastically reducing water consumption and significantly increasing cost savings.

Design Features

- Exclusive self-actuating Thermoloid® wax blend thermal actuator

- All Stainless-steel body, fittings, spring, and plug

- Corrosion-resistant – long service life

- Ram-type plug for tight, reliable shutoff

- Operates in a narrow temperature band

- Unaffected by pressure variations

- Fail-safe design – fails open

- Optional side port feature allows flushing debris from inside valve

Benefits

- Self-operating – no external power source required

- Drastically decreases seal water consumption

- Increases water treatment efficiency

- Eliminates dry runs due to operator error

- Increases seal life

- Expands mechanical seal use to more applications

- Decreases operating cost

- Quick and easy installation

Seal Water Savings Example

To illustrate the water savings from the case study below that can be realized with EcoFlow‘s mechanical seal support system, we’ve used a typical seal manufacturer’s recommendation of 2.6 GPM to be used to flush the seals versus EcoFlow’s 0.05 GPM, operating 8 hours a day, 5 days a week (2080 hours per year).

Recommended: 2080 hours x 2.6 gallons per minute x 60 minutes = 324,480 gallons of water per year.

W/ EcoFlow: 2080 hours x 0.05 gallons per minute x 60 minutes = 6,240 gallons of water per year.

In our calculation, EcoFlow® can save ~318,000 gallons of water per year.

Read the complete case study: EcoFlow Sugar Produce Case Study

Ordering

PART NUMBER1 | DESCRIPTION |

241-100000-XXX | 1/4” EcoFlow® SS |

241-100100-XXX | 1/4” EcoFlow® SS w/ side port |

241-111000-XXX | 3/8” EcoFlow® SS |

241-111200-XXX | 3/8” EcoFlow® SS w/ side port |