Operation

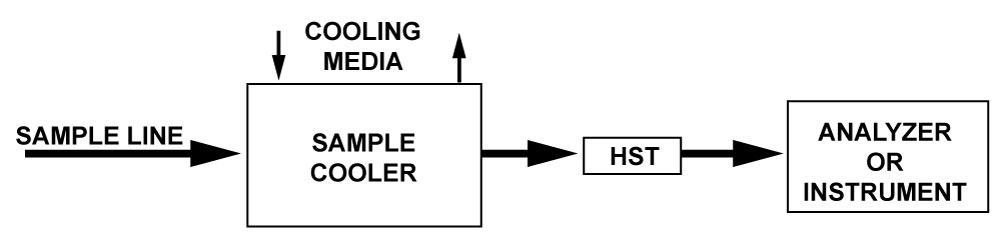

The HST (High Sample Temperature) automatic thermal shutoff valve senses the sample temperature after the sample cooler. Under normal conditions, the valve is wide open, so the sample fluid passes through the valve. The valve’s internal thermal actuator is always sensing the fluid temperature. If the temperature exceeds the valve’s set point, the HST will close to protect expensive and delicate analyzers and other instruments downstream from over-temperature damage.

The HST will only open again once the sample temperature falls back below the valve’s set-point. Low coolant flow, total loss of cooling water, or unusually high sample temperatures are typical reasons the HST self-operating protective device should be considered for your high-water temperature shutoff system.

Typical Applications

Excessively hot samples can cause damage to expensive and sensitive hardware and electronics. For process analyzers and similar instrumentation, it is crucial to ensure that the process sample fluids are consistently below the maximum allowable temperature for such instruments.

Sample coolers are commonly used to reduce sample temperatures to acceptable limits. In the event of a loss of cooling fluid to the sample cooler or if the desired sample temperature is exceeded, the HST thermal shutoff valve will close to prevent equipment damage.

Design Features

- Exclusive self-actuating Thermoloid® blend wax thermal actuator

- Ram-type plug provides tight shutoff

- Operating temperatures unaffected by variable inlet pressures

- Wide choice of temperature set-points available

- Corrosion-resistant – all stainless-steel construction

Benefits

- Self-operating – no external power source required

- Automatically controls flow based on fluid temperature

- Protects expensive and delicate sample analyzers

- Automatically resets when the sample cools

- Superior value vs. more expensive electric valves

- Easy installation

Ordering

PART NUMBER | DESCRIPTION |

254-000000-XXX | 1/2” HST (EPDM Seals) |

254-001000-XXX | 1/2” HST (Viton® Seals) |

254-002000-XXX | 1/2” HST (Kalrez® Seals) |

254-11X000-XXX | 1/2” HST-XXX-S6-X |