Operation

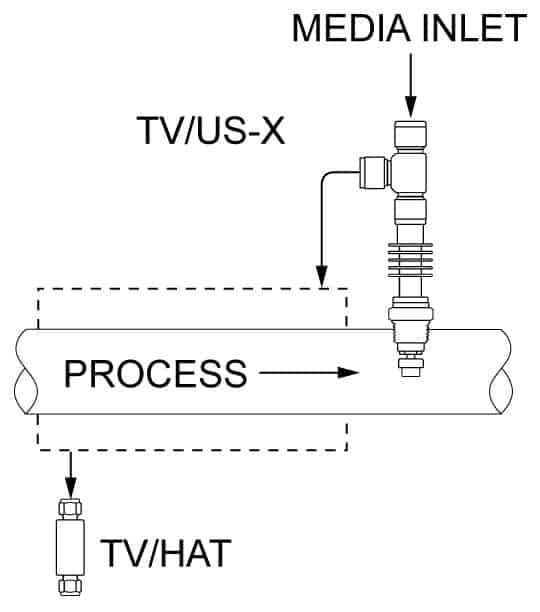

The self-actuating, thermostatic TV/US-X (Tube Fitting/Ultra Surface Sensing) sample cooler control valve operates the same as the US/S-X valve where the sensing end is either immersed in the process fluid or mounted non-invasively via a hose clamp on the outside of the pipeline. The two differences are that the heating media is connected with tube compression fittings instead of pipe fittings and the Cv is around half of the US/S-X valve.

When immersed in the process fluid, the thermal actuator in the valve automatically senses when the temperature rises above the valve’s set-point and modulates closed to keep the process fluid heated at a specified temperature within a 10°F differential. For example, a 90°F valve would open at 90°F and close at 100°F, always keeping the process fluid between 90 – 100°F.

Typical Applications

These self-contained and compact thermostatic sample cooler control valves can maintain very tight temperature control of any number of control loops using steam, liquid phase heat transfer media such as Dowtherm®, hot water, hot oil, glycol, compressed air, etc. Sample heating applications are commonly controlled by the TV/US-X, but they can be used whenever accurate, low cost control is required.

The reverse-acting model, TV/US-XR (Tube Fitting/Ultra Surface Sensing) can be used to regulate flow to protect a system or process from overheating by operating on rising temperatures to allow cooling fluid in.

Design Features

- Exclusive self-actuating Thermoloid® wax blend thermal actuator

- All stainless-steel construction

- Compact low mass – fast response

- Ram-type plug for reliable shut off

- Narrow temperature band

- Unaffected by pressure variations

Benefits

- Self-operating – no external power source required

- Prevents process overheating

- Discharges minimum amount of media for temperature control

- Maintains optimal process temperature

- Quick and easy installation

- Long service life

Ordering

PART NUMBER1,3,4 | DESCRIPTION |

783 - 0X0000 - XXX | 3/8” TV/US-X |

784 - 0X0000 - XXX | 1/2” TV/US-X |