7 Benefits of Thermostatic Control

When it comes to system performance in mission-critical aerospace and defense applications, thermal control is a leading factor in successful operation. Having an effective flow control device to balance temperature within the system ensures a more efficient and stress-reduced operation.

There are two commonly implemented types of flow control valves for A&D applications, solenoid valves and thermostatic valves.

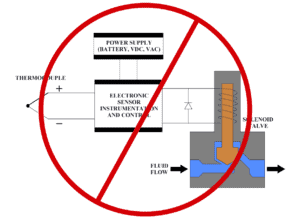

Solenoid valves require a complex set-up with multiple components external to the valve, as well as a source of DC power to operate which tends to increase installation expenses, space requirements, and the risk of operation failure in the case of a power outage or component failure.

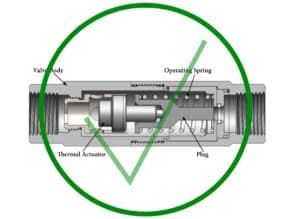

ThermOmegaTech recommends thermostatic valves as the #1 thermally controlled flow solution for A&D applications. Precise, compact, and reliable, thermostatic valves are entirely self-powered and respond to narrow temperature variations to precisely control system flow, without the need for an external power source.

7 Benefits of Thermostatic Valves

Thermostatic control valves can be used for heating or cooling to effectively control temperature in various applications. Simplistically designed with paraffin wax actuator technology, these temperature control valves are versatile with a number of advantages that solenoid valves simply can not beat.

- Self-actuating

- Highly-repeatable

- Long service life

- Maintenance-free

- Few moving parts

- Compact

- Unaffected by extremes – ideal for hazardous environments

To learn more about the difference in these types of valves check out our comparison sheet.