Operation

The TV/HAT-RA-LP (reverse-acting heat actuated trap valve with tube fittings and a leak port) is controlled by a thermally operated reverse acting cooling valve actuator and should be installed on the cooling water outlet of the equipment as an after-flow controller. Since it is what we classify as reverse-acting, the valve will open when the fluid temperature rises to the valve’s set point.

At start-up, this valve is in its closed position, except for the “control leakage”, which allows a small amount of flow to sense the changing fluid temperature upstream in the system. As the outlet water temperature increases to within the set operating range of the TV/HAT-RA-LP, the reverse acting cooling valve actuator modulates the valve open to allow a flow of cool water through the system.

If the cooling water temperature is above the valve’s set point, the valve will continue to modulate open allowing additional flow. As the outlet water temperature falls, the valve then modulates back towards the closed position, reducing flow. This modulating action maintains a relatively constant outlet fluid temperature.

Typical Applications

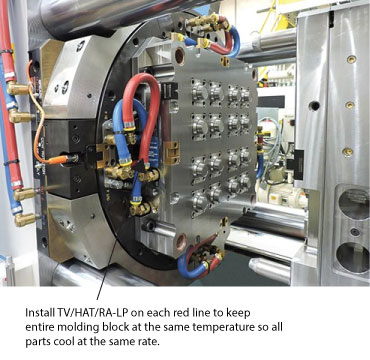

TV/HAT-RA-LP valves are ideal for controlling cooling water for water-cooled compressors, die-casting equipment, welding equipment, electrical equipment, molding equipment, and other systems with engines or heat exchangers.

Design Features

- Exclusive self-actuating Thermoloid® blend paraffin wax actuator

- Compact, low mass for fast response

- Corrosion-resistant – Long service life

- Operates in narrow temperature band

- Stainless steel body, fittings, spring, and plug

- Ram-type plug for tight reliable shutoff

- Leak port (LP) senses upstream temperature

Benefits

- Self-operating – no external power source required

- Unaffected by pressure variations

- Improves system efficiency

- Wide choice of set points

- Operates in any position

- Easy installation

Ordering

PART NUMBER | DESCRIPTION |

223 - 102X00 - XXX | 3/8” TV/HAT-RA-LP 1⁄4 GPM |

223 - 112X00 - XXX | 3/8” TV/HAT-RA-LP-SW3 1⁄4 GPM |

224 - 102X00 - XXX | 1/2” TV/HAT-RA-LP 1⁄4 GPM |

224 - 112X00 - XXX | 1/2” TV/HAT-RA-LP-SW3 1⁄4 GPM |