Operation

The ITCH (Instrument Temperature Control Heater) Assembly is 100% mechanical, operating solely based on ambient and/or fluid temperature changes controlled by a wax motor.

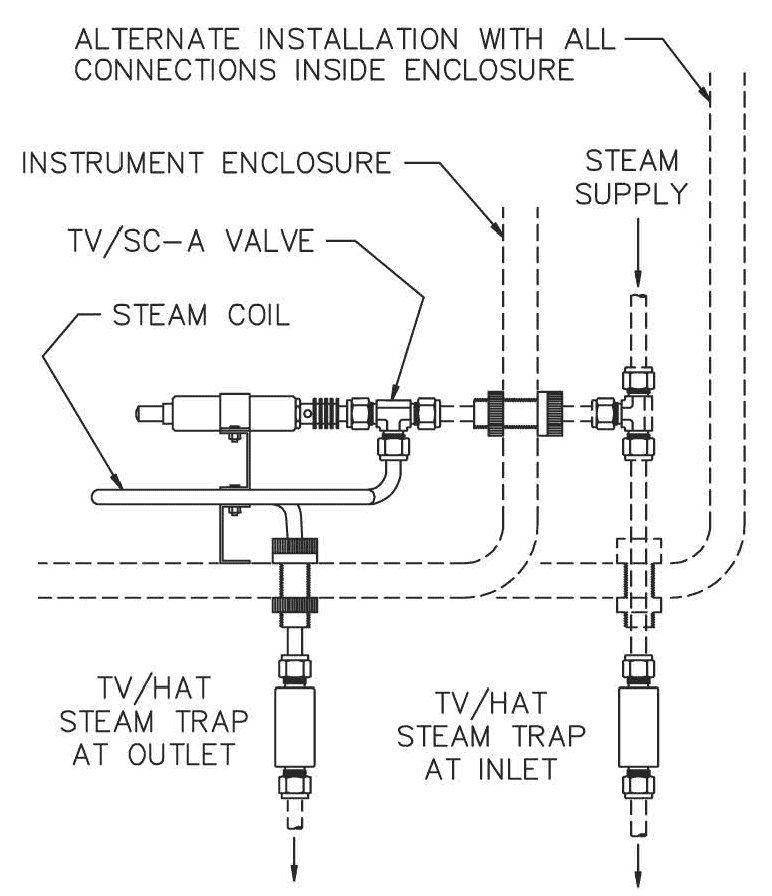

The thermostatic wax actuator located at one extreme of the TV/SC-A valve operates like the thermostat in an oven, automatically senses the internal enclosure temperature, and regulates steam flow to the heater coil to maintain the desired temperature. The TV/HAT at the steam inlet keeps the steam supply hot to prevent freezing even when the TV/SC-A valve is closed. The TV/HAT at the coil outlet regulates condensate discharge temperature for maximum economy with minimized overheating potential.

The ITCH Heater Assembly comes complete with a steam coil, mounting bracket, and TV/SC-A valve assembly, two TV/HAT valves, and two weather-tight bulkhead fittings for 3/8 tubing connections.

The TV/SC-A and TV/SC-I valves (with external connections) are also available separately if you do not require a complete assembly.

Typical Applications

The ITCH Assembly, instrument temperature control valve assures accurate temperature control in an instrument or analyzer enclosure. It will maintain enclosure temperature accurately over a wide range of ambient temperatures with steam supply pressures from 15 PSIG (1 BAR) to 200 PSIG (13.8 BAR) without danger of overheating delicate instruments.

This self-contained unit provides a reliable, economical alternative to costly, hazardous electric heating. No special NEMA-7 or 9 housings are required even in potentially explosive environments.

Design Features

- Exclusive self-actuating Thermoloid® blend wax thermal actuator

- All stainless-steel construction

- Compact, low mass – fast response

- Corrosion-resistant – long service life

- Ram-type plug for tight reliable shutoff

- Operating temperatures unaffected by variable inlet pressures

- Wide choice of set-points available

Benefits

- Self-operating – no external power source required

- Economically controls steam flow

- Maintain enclosure temperature accurately over a wide range of ambient temperatures

- Eliminates danger of overheating

- Complete kit with standard tube connections for quick and easy installation

Ordering

PART NUMBER 1 | DESCRIPTION2 |

753-000000-XXX | 3/8” ITCH ASSEMBLY |