How do I find pricing and availability on your products?

Go to the Find Your Rep tab in the blue banner on the main page, Select the appropriate Plumbing, Industrial, or Railroad field, and select your State or Country if you are seeking an International rep.

My customer didn’t need the product – can I return it?

Yes, although there may be a 25% restocking fee depending on to circumstances. Please contact your salesperson for additional details.

Can you send me a drawing/spec sheet/submittal?

Yes, if it’s an existing one on file. If not, an REA form will need to be filled out for one of the Engineers to create.

What size valve do I need to protect a water line from freezing?

The size and number of valves is determined by first calculating the flow required to prevent freezing. Once we know the required flow rate and your water pressure, we calculate the required valve flow coefficient, Cv. Any valve or combination of valves with a total Cv greater than or equal to this will provide adequate protection. Refer to our Application Profile #3 for calculation.

What is the difference between a bleeder valve and a drain valve?

Bleeder valves or modulating valves, bleed off near freezing water from exposed piping and allow the system to refill with warmer re-supply water. The bleeder valve will close when the temperature of the water or fluid is above the set point and the danger of freezing is over. Drain valves are typically positive action valves that open or release at a set temperature. The valve does not close until the system is completely drained and the valve can be manually closed or reset. Refer to our HAT/FP valves for additional information on bleeder or drain type valves.

For what kind of freeze protection applications would you recommend a snap acting valve over a modulating valve?

Fixed volume systems, such as storage tanks, water cooled engines, or cooling tower pumps typically require the system to be completely drained to prevent freezing. A simple, but safe method is to wait until the water temperature approaches freezing and then drain it as quickly as possible. Refer to our Guru® DL 2.1 Series for product information.

We have exposed water lines throughout the plant which distribute potable water to emergency safety shower and eyewash systems. What can I do about these lines being overheated by solar radiation or other heat sources?

Over temperature water can cause serious burns to employees using safety shower equipment. Modulating scald protection valves are designed to open and drain off when an overheated water temperature is sensed. Typical set points of 105°F to 115°F control water temperatures to safe levels. Refer to our model HAT/SP valve for product information.

How can I solve overheating problems on a centrifugal booster pump when water demand is low?

We manufacture several pump thermal relief valves specifically for this application, offering various end connections, operating pressures, and materials of construction. All are self-operating and require no power or signal connections of any kind. For example, Refer to the popular ECONO/HAT-RA valve for a product example.

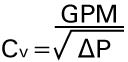

What is Cv and how do I use it to size valves?

Flow coefficient, commonly designated as Cv, is a measure of the resistance to flow. This factor must be measured using standardized flow tests specifically for this purpose, even though estimations can sometimes also be made by calculations alone. Once the factor is known, it is used in standardized equations to calculate flow or related parameters.

where…

GPM = water flow in gallons/minute

P = pressure drop in psi

We have problems with both overheating and freezing of instruments mounted inside of instrument enclosures. What can I do to solve this problem?

Refer to our models HAT/RA-LP Valve, HAT/FP Valve, TV/SC-I Valve & ITCH Valve for product information.

What product is best for a temperature diverter that will send fluid through the cooling circuit when the trigger temp is reached? The product needs to work with Glycol fluid AND Hydraulic mineral fluid.

The customer should use an M/D diverting application (95 – 104F) using a 90-degree valve (+/-8F, so calibrate 82 – 98F). Our valves have a fixed temperature setting and cannot be field adjustable. The only way is to purchase a different temp cartridge and swap it out. Please call your salesperson if you need more information.

How do I improve the efficiency of our hot water glycol pipe tracing system? We’d like to add temperature control valves to different heat tracing lines so we can send the flow where we need it. However, the HAT valves are sensing temperature from the glycol line for tracing instead of sensing the product temperature.

This application would use a US Series type valve to keep the media hot. Using the TV/HAT is only required if steam is the heating medium, otherwise it recirculates back to the glycol heater tank.

How does your rebuild program work?

Please see https://www.thermomegatech.com/guru-rebuild-program/ for Rebuild Program details.

How do I track the status of my order?

Call your salesperson at the company where you purchased the product.

Can I expedite my order?

Usually, yes – depending on whether all the components are in-house or readily available. There may be an additional fee associated. Please contact your salesperson for details.

Have an Application or Technical question?

Call us at 215-798-5978 and ask for Technical Assistance. If not urgent, email us at engineering@thermomegatech.com.

I am having a technical issue with a product – can I set up a warranty return and replacement?

Yes, please contact us at 215-798-5978 and ask for Sales to assist with your product.