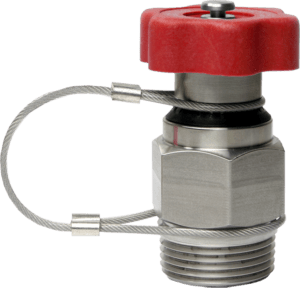

GURU® Plugs for Locomotives

ThermOmegaTech® offers a rebuild program for the self-actuating GURU® plugs that protect thousands of locomotives from freeze damage every year. Our rebuild program allows you to return your old GURU® plugs to be cleaned, refurbished, and retested so you essentially get back a brand new valve.

Recommendations on Maintenance

ThermOmegaTech® recommends changing the GURU® Plug every 18-24 months. The characteristic tendency of the GURU® Plug actuator is to lose a small amount of stroke as it ages beyond one year. This loss of stroke causes the release temperature and the manual reset temperature to creep upward. While this is a “safe” tendency for freeze protection, the upward creep can eventually cause nuisance dumping.

The GURU® Plug’s colored cap serves as a visual indicator of the year it was built. Five colors rotate, each associated with a year. View the cap color chart here. The month and year that the valve was manufactured is also laser marked on the top of each cap.

How the Program Works

- Valves are returned with a purchase order to our facility

- All components are scrapped except cartridge body and hex nut

- New thermal actuator and components are assembled into the cartridge

- The cartridge is 100% tested and inspected

- Hex Nut is assembled and inspected

- The cartridge is inserted into the Hex Nut

- Completely assembled GURU® Plug is leak tested

- 100% Final pop test is completed

.Contact our Rail Product Experts to Place Your Rebuild Order Today!

GURU® PC for Passenger Cars

GURU PC® valves, used to protect passenger rail cars’ potable water-bearing systems from freeze damage, are also recommended to be replaced every 18-24 months. We recommend this because of the characteristic tendency of the thermal actuator losing a small amount of stroke as it ages beyond one year. This causes the release temperature to creep upward, eventually causing nuisance dumping but not compromising freeze protection.

To facilitate easy in-line maintenance and minimize downtime, we offer replacement cartridge assembly kits that allow for field servicing without the need to return the valve to our facility.

How it Works

- Contact our Railroad product team to purchase a replacement cartridge kit

- After receiving the kit, remove all internals from the installed valve

- Clean threads, internal surfaces of the body, and valve port of all dirt/grime and mineral buildup

- Insert replacement cartridge parts into the body

- Test the valve by spraying the actuator with freeze spray

Please note that ThermOmegaTech® does not offer a rebuild return program for GURU® PC valves. All maintenance and replacements should be performed in the field using the provided kits.

For detailed installation and maintenance instructions, refer to the following resources:

- 3/4″ GURU PC Rebuild Kit Installation and Maintenance Instructions

- 1″ GURU PC Rebuild Kit Installation and Maintenance Instructions