The below case study features the EcoFlow thermostatic double mechanical seal support valve, a major U.S. sugar producer, and a substantial amount of savings.

Install Location Profile

A major U.S. sugar producer had several hundred pumps throughout their plant. Their pumps were either using packing, which required constant maintenance or using mechanical seals, which required a water supply to cool and flush it.

In the latter instance, the water is usually either returned to a seal water tank or dumped to drain. Any water that ends up on the floor or in a drain finds its way back to process and must be evaporated (large cost) or sent to wastewater (even larger cost). Both setups resulted in unnecessary costly water usage.

Prior to the adoption of ThermOmegaTech’s EcoFlow Mechanical Seal Support Valve, the plant faced several challenges:

- The plant could not use mechanical seals on their pumps due to the large water demand and up-front expense of a closed recirculation system.

- Packing was used in all pumps instead of double mechanical seals, which required leakage and constant maintenance.

- Expensive seals were damaged every year due to accidental dry running.

How The EcoFlow Helped

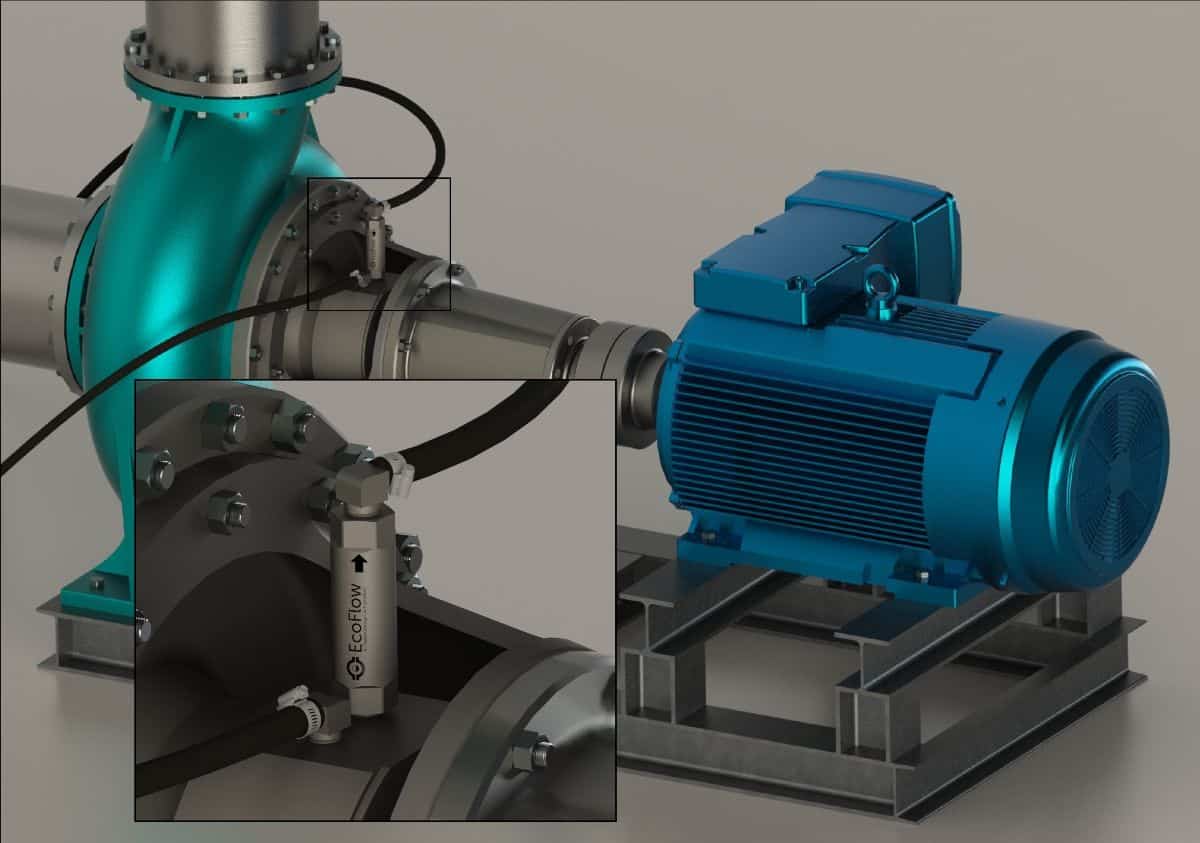

EcoFlow valves were placed on the seal water outlet of their pumps’ double mechanical seals to control the seal water temperature. The EcoFlow valve senses the seal water temperature and will modulate open to discharge the water if the temperature is too high, then modulate closed again once the flow cools to below the valves’ set-point.

More than 20 EcoFlow valves were initially installed at the plant. With great success and zero valve failures after two years, the plant is now planning to double its usage to a total of over 40 valves by the end of summer 2017.

Since installing EcoFlow thermostatic control valves, the plant has reduced dry running damages from four seals annually to zero. The implementation of EcoFlow valves has also reduced maintenance expenses, and provided an opportunity to use double mechanical seals in a situation which otherwise would not have been possible:

“EcoFlow allowed us to install double mechanical seals in places that we couldn’t have done so without an expensive closed loop seal water system. Now we run water to the seal and let the small amount of water the valve lets pass go to drain. We do not spec pumps with anything other than mechanical seal any longer. 100% of our replacements are now either a single or double seal, and each double gets the EcoFlow.”

Results

By installing EcoFlow valves the plant was able to drastically decrease maintenance costs and reduce the amount of water that was sent to the drain.

“The seal manufacturer recommends 2.6 Gallons Per Minute to keep the seal below 180°F, though the 135°F, EcoFlow is putting out about 3 Gallons Per Hour.”

Assuming the seals operate 8 hours per day, 5 days per week, this equates to 2,080 hours of operation annually.

= 324,480 gallons per year