In various industrial applications, maintaining the right temperature is crucial to ensuring the safety and efficiency of equipment. A thermal relief valve is one essential component in achieving this.

Let’s explore how thermostatic thermal relief valves can improve your system’s performance and lifespan, increase efficiency, and prevent damage.

Understanding Thermal Relief Valves

A thermal relief valve is a safety device designed to release overheated water from systems to prevent seal degradation and other damages caused by excessive temperature. When the fluid in a closed system heats up beyond a safe level, the valve opens to allow the overheated water to drain and cooler fluid to enter the system from the reservoir.

Thermal Relief Valve Function: The primary function of a thermal relief valve is to maintain safe temperature levels, preventing potential damage or catastrophic failure. This is particularly important in systems where fluid is prone to overheating, such as water in booster and fire pumps.

The choice of thermal relief valve depends on the application, operating conditions, temperature settings, and regulatory requirements. The value is undeniable. The cost of a thermal relief valve is minimal compared to the damage caused by overheating—from component replacement to labor for repairs to the cost of interrupted operations.

ThermOmegaTech offers two industrial thermal relief valve models. The ECONOHAT/RA is designed to protect booster pumps in low to medium pressure systems by releasing excessively heated water. For higher pressure applications, such as fire pumps, the HAT/RA-HP model provides the same thermal protection.

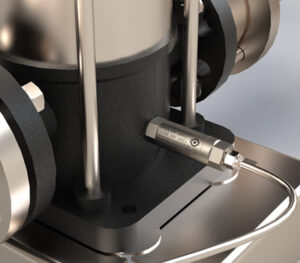

Thermal Relief Valve Design

The construction and components of a typical thermal relief valve can vary depending on its specific application and manufacturer. It typically consists of the following components:

Body: Made from durable materials such as stainless steel or brass, ensuring longevity and resistance to corrosion.

Thermostatic Element: The thermostatic element, such as a thermal wax actuator, is designed to open the valve at a specific temperature, allowing overheated water to escape.

Outlet: The outlet directs the relieved water to a safe location, preventing personnel harm or equipment damage.

These valves are self-actuating, modulating open and closed based on fluid temperature alone and unaffected by pressure variations. ThermOmegaTech’s stainless steel thermal relief valves are also NSF/ANSI/CAN 61 & 372 Certified.

Uses and Applications of Thermal Relief Valves

Using thermal relief valves is a safety measure that prevents damage and ensures the reliability of various industrial processes and equipment. Seals are the most susceptible component, but the entire system is at risk if temperatures rise to extreme levels. Some industries that utilize these valves are chemical processing, oil and gas, water treatment and supply, manufacturing, and fire protection systems.

Examples of Equipment and Systems

Booster Pumps: Used in domestic water supply systems to maintain consistent water pressure throughout a building. Because they are one of the first pieces of equipment installed during the construction of a new building, a booster pump can operate at a far lower capacity than its design point. This causes heat build-up while idling. A thermal relief valve like the ECONOHAT/RA senses that temperature spike, releases hot water, and spares critical components from the dangers of excessive heat.

Fire Pumps: Used on fire trucks to provide a steady flow of high-pressure water from various sources, such as hydrants, tanks, or natural water bodies. Overheating can occur when the pump operates for extended periods without sufficient water flow. Our HAT/RA-HP valve ensures the pumps do not overheat during use, which is crucial for effective firefighting operations.

How these Valves Operate

ThermOmegaTech’s thermal relief valves are installed on the pump casing and configured with a customer-selected open temperature to provide thermal protection. When the water in the pump starts rising to temperatures higher than specified, the thermal actuator within the valve modulates open, discharging the hot water. Cooler water from the water supply or tank then replaces the discharged water, lowering the temperature inside the pump.

Subsequently, the valve modulates closed once the temperature returns to acceptable levels. This modulating action maintains a relatively constant fluid temperature even as operating conditions vary. The discharged water can be collected, reused, or repurposed to reduce waste.

Conclusion

Thermal relief valves play a vital role in maintaining the safety and efficiency of various industrial systems. By preventing temperature build-up, these valves protect equipment, ensure uninterrupted operation, and increase the lifespan of your systems. The ECONOHAT/RA and HAT/RA-HP valves exemplify the reliability and precision needed for these critical applications.

Visit our pump thermal relief page for more information on our thermal relief valves and other innovative solutions. Have questions? Contact us today!