By Nick Tallos

“I turned on the water in the shower and waited for 10 minutes. Warm water finally started flowing, however, it never lasted more than a minute and alternated mostly with cool to cold water.”

Image via Pexels.

That’s the exact quote extracted from an online review of a guest who rated a hotel in Pennsylvania on Tripadvisor.com. The reviewer gave the hotel a rating of two out of a possible five. The site is full of similar comments from guests complaining about how long it took them to get hot water when they wanted to take a shower or wash their hands.

In the hospitality industry, when a guest turns on the hot water in their room, most wait patiently for the water to run a while to the proper temperature. Guests do not like to wait too long for their hot water according to the International Hospitality Association.

In fact, they specifically address “the availability of hot water” as a factor for consideration in their quality standards and star rating systems that they set as the bar for multi-star ratings.

The cost to deliver domestic hot water to ensure customer satisfaction means the domestic hot water system must be balanced in a way that keeps the delivery time low. Until recently, that meant larger recirculating pumps, more recirculating flow, more wear and tear on your hot water system, and more cost.

Read more on Green Lodging News about domestic hot water systems.

From the Bucks County Courier Times Success Through Diversity

From the Bucks County Courier Times Success Through Diversity

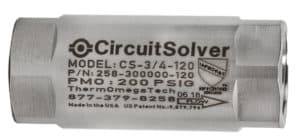

ThermOmegaTech, Inc has been honored by having two of our valves nominated for

ThermOmegaTech, Inc has been honored by having two of our valves nominated for

The

The

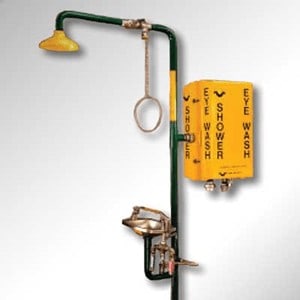

Keeping your safety shower working at optimum performance is important, no matter what time of year. However, cold winter temperatures can make this especially difficult. Water can freeze in supply lines, clogging the system and shutting off flow. And because water expands as it freezes, internal pressure in the line can increase enough to break steel pipes and their associated valves and fittings. The result can be costly replacement parts, in- creased labor costs, and a shower that’s out of commission while it’s being repaired.

Keeping your safety shower working at optimum performance is important, no matter what time of year. However, cold winter temperatures can make this especially difficult. Water can freeze in supply lines, clogging the system and shutting off flow. And because water expands as it freezes, internal pressure in the line can increase enough to break steel pipes and their associated valves and fittings. The result can be costly replacement parts, in- creased labor costs, and a shower that’s out of commission while it’s being repaired.