ThermOmegaTech®, a self-actuating thermostatic temperature control technology pioneer, brings over four decades of expertise to various industries, including industrial and commercial plumbing, aerospace, and defense. This year, the Industrial team is excited to participate in the ASSP Safety Show in Denver, Colorado, from August 7th to 9th, at booth #1734.

“Safety is our top priority at ThermOmegaTech,” said Industrial Sales Manager Andy Reichlin. “We’ve developed innovative tepid water solutions for emergency showers and eyewash stations that meet OSHA and ANSI standards, and we ensure water lines don’t freeze or overheat, protecting personnel and creating a safe working environment.”

At Booth #1734, you will discover their thermostatic solutions for safety and maintenance, including the Therm-O-Mix® Tepid Water Delivery Station, ESS Tepid Water Heater, Freeze and Scald Protection Valves, and STVM® Washdown Station.

THERMOMEGATECH PRODUCTS

Federal regulations require that any facility where workers may be exposed to hazardous or corrosive materials must have immediate access to a tepid water emergency drench system to protect the eyes and body in the event of accidental exposure.

The Therm-O-Mix® station consistently supplies tepid water on demand to these fixtures to meet OSHA and ANSI Z358.1 safety requirements.

Read more about ThermOmegaTech’s Therm-O-Mix® station here.

Factory-packaged with ThermOmegaTech’s Therm-O-Mix® WWM mixing valve, the ESS (Emergency Shower Water Heater) combines cold and tank-heated hot water to deliver a constant 85°F tepid water outlet temperature at the point of use for safety showers and eyewash stations.

See how the ESS works here.

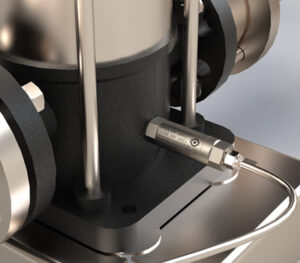

ThermOmegaTech’s self-actuating temperature control valves are the ideal solution for

Freeze and Scald Protection. When temperatures approach freezing, these thermostatic valves sense water or air temperature and modulate open to bleed off the cold water in the line.

The scald protection valve senses and purges the over-temperature water from outdoor water supply lines that get too hot and could damage equipment or scald personnel. These valves are typically installed in safety showers and eyewash stations to protect personnel.

See how the Freeze Protection valve works here.

ThermOmegaTech® supplies an innovative solution to difficult-to-maintain steam and water mixing stations, providing a high-temperature washdown for sanitization procedures at processing plants.

See how the STVM Washdown station works here.

How can we help keep your personnel and equipment safe from damage?

Stop by Booth #1734 for more information.

ThermOmegaTech® is eager to connect with end users for case studies and testimonials about our valves, STVM Washdown Station, and the Therm-O-Mix Station.

About ThermOmegaTech®:

For 40 years, ThermOmegaTech® has been a leader in designing and manufacturing self-actuated thermostatic valves and actuators. Founded in 1983, ThermOmegaTech® is a privately held organization with 40,000 square feet of manufacturing and office facility near Philadelphia, Pennsylvania.

The company provides innovative thermostatic solutions for various applications, including freeze protection, scald protection, mixing & diverting, steam traps, thermal bypass, tepid water delivery, washdown, balancing, drain tempering, and many other applications where temperature control is critical. Key industries it serves include railroad, commercial plumbing, aerospace, defense, and industrial.

ThermOmegaTech® offers an array of standard valves and specializes in manufacturing highly engineered custom designs to meet your project’s needs. The engineering, manufacturing, assembly, testing, inspection, sales, and customer service departments are all located in one facility for maximum efficiency and effective communication. ThermOmegaTech® has been ISO 9001-certified for over two decades and achieved AS9100D certification in 2019.

For more information, please get in touch with ThermOmegaTech here.