In food processing, dairy, beverage, chemical, petrochemical, and pharmaceutical facilities maintaining a clean environment is critical to product quality and operational efficiency. Washdown stations are used to quickly and efficiently clean and sanitize equipment in place between production runs or shift changes.

ThermOmegaTech® offers three different washdown station options:

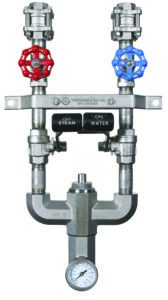

STVM® Steam & Water Washdown Station

The STVM® Washdown Station provides an effective high temperature wash in an easy-to-maintain package. Utilizing our patented Silent Venturi Mixing Valve (STVM®) technology, this washdown station mixes together steam and water to produce a high-powered wash at a user-defined temperature.

Designed to be self-scouring, the mixing valve prevents mineral buildup in tight spaces, decreasing maintenance frequency. To further reduce time spent on required regular maintenance, the unit is in-line serviceable. The user simply switches out the STVM® cartridge with another on hand and the unit is back up and running in minutes.

Safety is our priority, so every STVM® Washdown Station has two built-in safety features – interlocking ball valves to prevent steam-only operation, and an automatic shut-off when output is 15°F over the unit’s temperature set-point (either 150°F or 185°F) or when cold water flow is interrupted.

HCX Water & Water Washdown Station

For facilities without an available steam supply, the HCX Washdown Station is an ideal solution. This unit utilizes individual globe valves to mix hot and cold water to a user-defined temperature, clearly displayed on the integrated temperature display gauge.

For facilities without an available steam supply, the HCX Washdown Station is an ideal solution. This unit utilizes individual globe valves to mix hot and cold water to a user-defined temperature, clearly displayed on the integrated temperature display gauge.

To prevent accidental scalding, the unit is offered with our unique SmartFlow feature. This in-line, over-temperature safety valve automatically stops flow should the unit’s output exceed a factory specified set-point.

HCS Single-Channel Washdown Station

The HCS Washdown Station simplifies washdown applications even further, providing a high-powered single stream of either cold water or pre-heated hot water at the turn of a ball valve. The unit employs an integrated temperature gauge to confirm output temperature.

The HCS Washdown Station simplifies washdown applications even further, providing a high-powered single stream of either cold water or pre-heated hot water at the turn of a ball valve. The unit employs an integrated temperature gauge to confirm output temperature.

These valves improve process efficiency, reduce system wear, maintain consistent product quality, conserve energy, and can save money.

These valves improve process efficiency, reduce system wear, maintain consistent product quality, conserve energy, and can save money. ThermOmegaTech®’s

ThermOmegaTech®’s  The CircuitSolver® is a domestic hot water system balancing valve that continuously and automatically adjusts the flow through each branch of a water recirculation system to maintain the specified temperature at the end of each branch, regardless of fluctuations in demand. The CSUA-PP combines the CircuitSolver® technology professionals trust and Viega® ProPress® ends for improved ease of installation.

The CircuitSolver® is a domestic hot water system balancing valve that continuously and automatically adjusts the flow through each branch of a water recirculation system to maintain the specified temperature at the end of each branch, regardless of fluctuations in demand. The CSUA-PP combines the CircuitSolver® technology professionals trust and Viega® ProPress® ends for improved ease of installation. The company expands its commercial plumbing line to now include the CSUSF – a sanitary flush balancing valve for domestic hot water systems

The company expands its commercial plumbing line to now include the CSUSF – a sanitary flush balancing valve for domestic hot water systems Warminster PA, June 29, 2017 – Thanks to customer and channel input, ThermOmegaTech® continues to identify new opportunities in the washdown market with both steam and hot water applications. To support the growing washdown line, ThermOmegaTech® is excited to announce the new

Warminster PA, June 29, 2017 – Thanks to customer and channel input, ThermOmegaTech® continues to identify new opportunities in the washdown market with both steam and hot water applications. To support the growing washdown line, ThermOmegaTech® is excited to announce the new  Warminster PA, March 8, 2016 – ThermOmegaTech®, a world leader in the design and manufacture of self-actuating temperature control technology, is expanding its

Warminster PA, March 8, 2016 – ThermOmegaTech®, a world leader in the design and manufacture of self-actuating temperature control technology, is expanding its  September 24, 2014 – Warminster, PA — Making its world debut at InnoTrans 2014, ThermOmegaTech, the market leader in North American locomotive freeze protection announces

September 24, 2014 – Warminster, PA — Making its world debut at InnoTrans 2014, ThermOmegaTech, the market leader in North American locomotive freeze protection announces